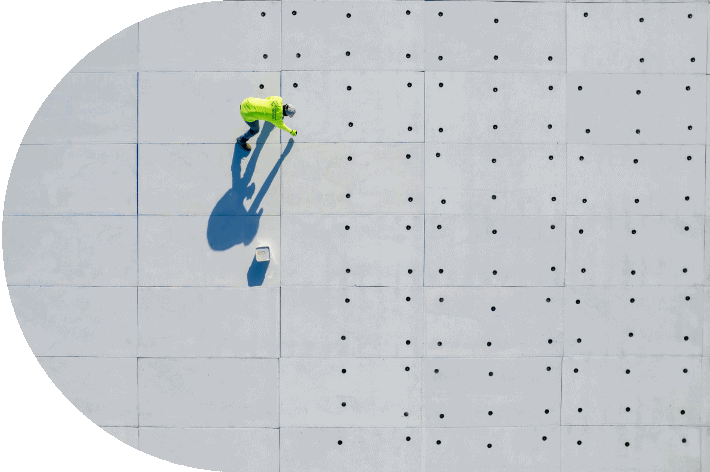

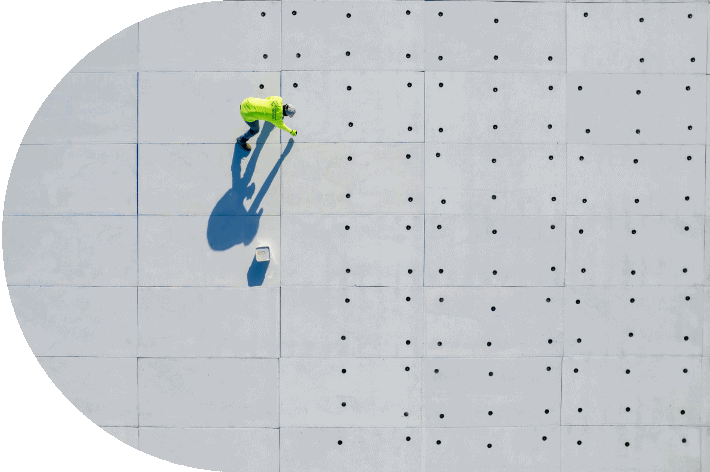

The power of circular thinking applied to high-performance building materials

Our purpose is to repurpose. Not just once, but again and again. At each UPFACTORY®, we transform upcycled beverage cartons and other paper and plastic packaging into highly resilient and infinitely recyclable roof cover board that delivers decades of protection.

New website coming soon

We are working hard to prepare new content for you. Stay tuned!